Product Center

Liquid Particle Counter HM-YT10

Product details

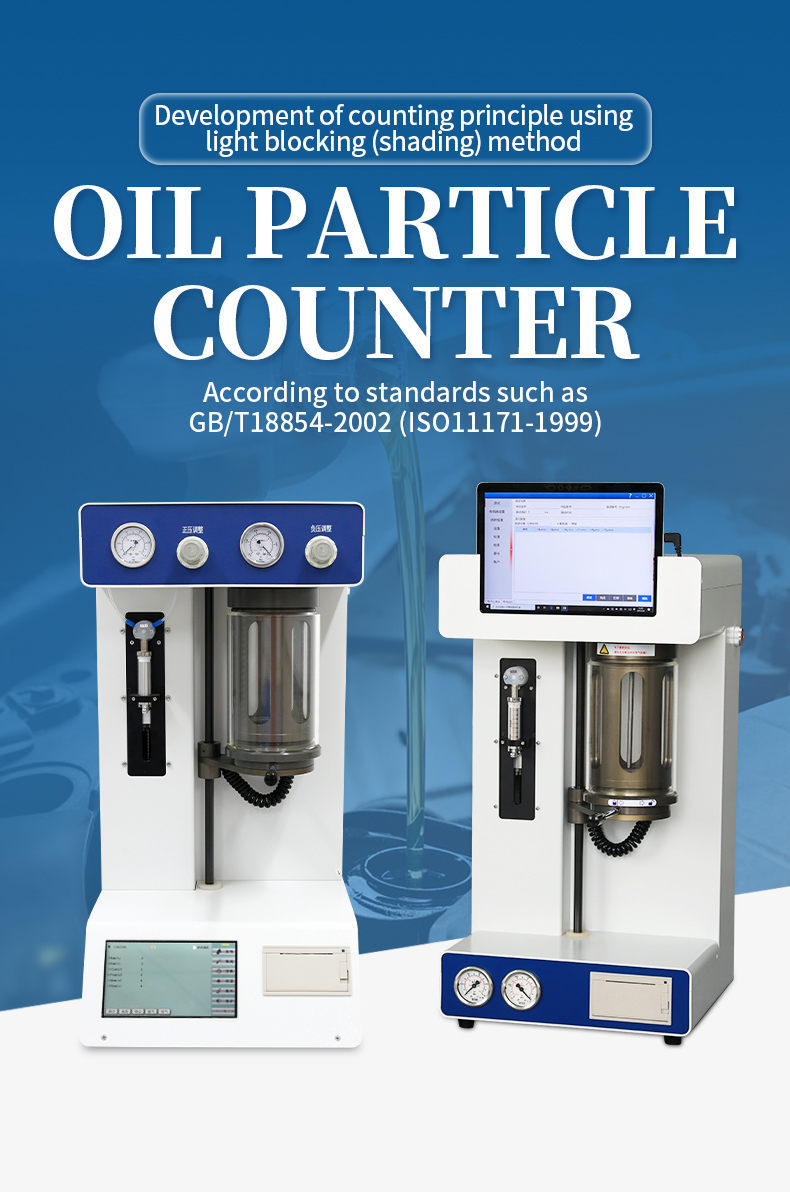

The liquid particle counter is based on standards such as GB/T 18854-2002 (ISO11171-1999). Developed using the principle of light blocking counting, it fully complies with the corresponding national military standards, national standards, and international standards. It can provide fast, accurate, reliable, and reproducible detection results and complete pollution monitoring and analysis reports, suitable for detecting particle pollution levels in hydraulic oil, lubricating oil, fire-resistant oil, insulation oil, and turbine oil. It can be widely used in aviation, aerospace, power, petroleum, chemical, transportation, ports, metallurgy, machinery, automobile manufacturing and other fields.

Main Features

Adopting the counting principle of photoresist (shading) method developed by the International Hydraulic Standards Committee

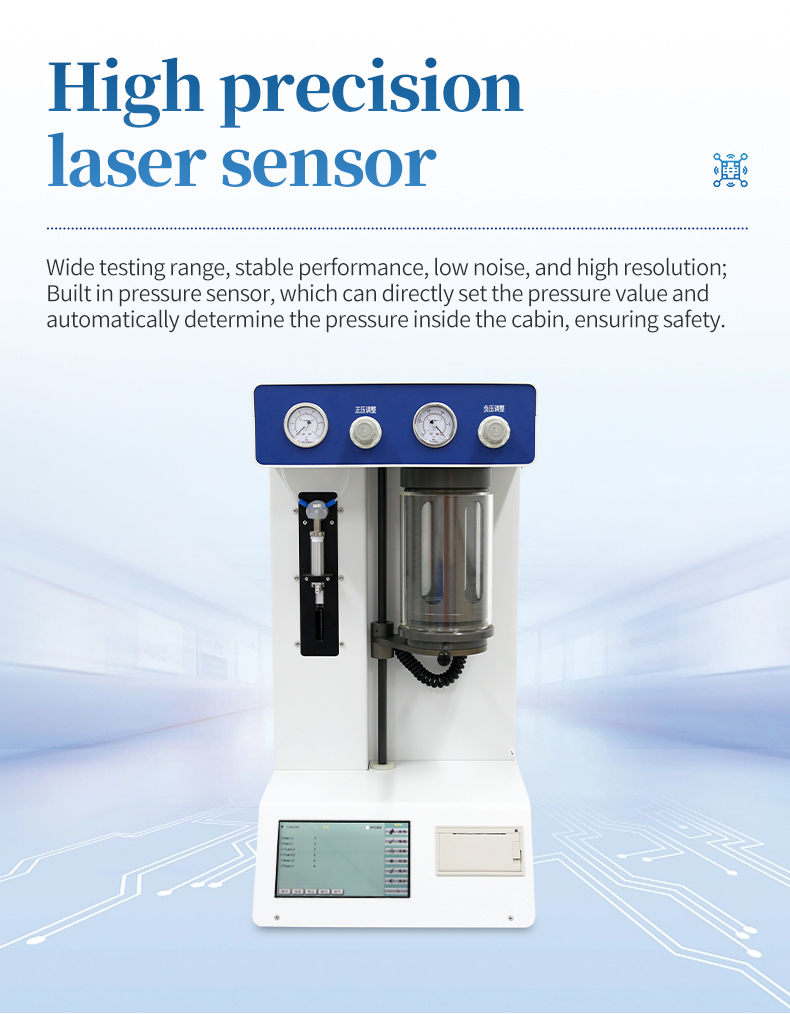

High precision laser sensor with a wide testing range, stable performance, low noise, and high resolution

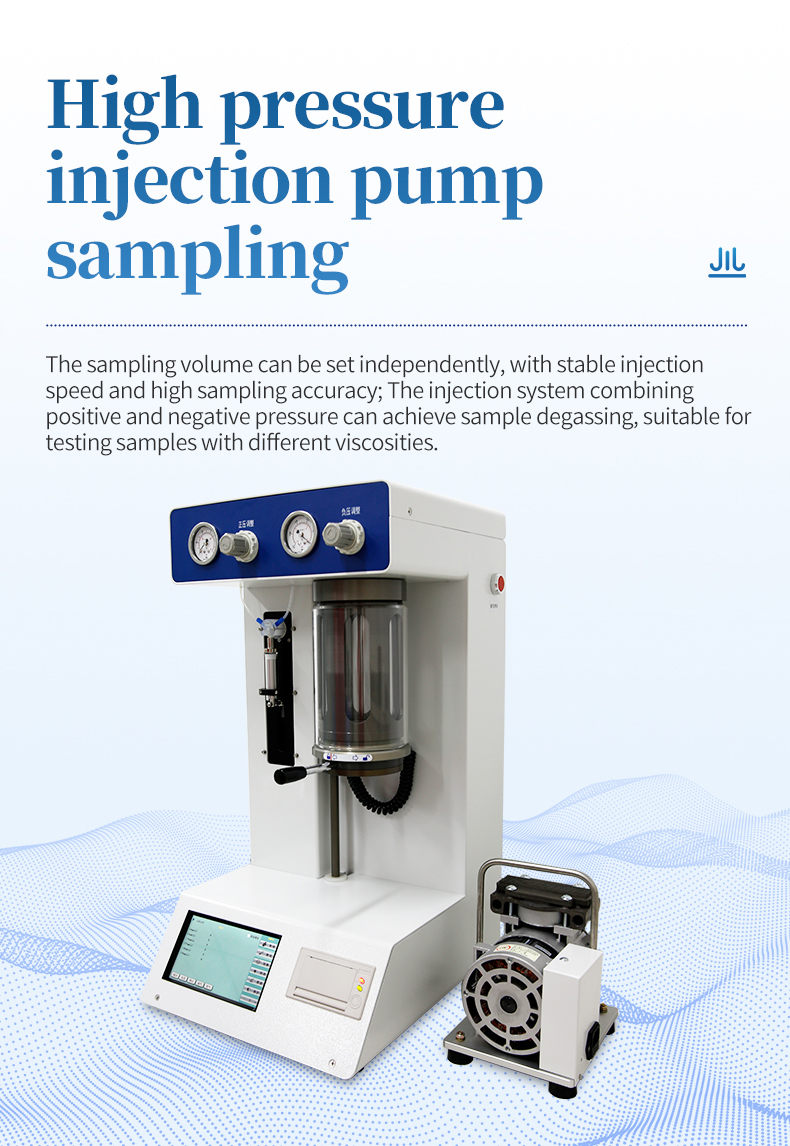

Adopting high-pressure injection pump sampling method, the sampling volume can be set by oneself, the injection speed is stable, and the sampling accuracy is high

The injection system combining positive and negative pressure can achieve sample degassing and is suitable for testing samples with different viscosities

Equipped with a built-in pressure sensor, it can directly set the pressure value and automatically determine the pressure inside the cabin to ensure safety

The host is equipped with an air purification system to ensure that testing is not contaminated, with a high degree of integration to avoid secondary pollution caused by the airtightness of the connection between the air pump and the testing system

Built in multiple calibration curves, compatible with all commonly used domestic and international standards for calibration

built-in GJB-420A、GJB-420B、NAS1638、GB/T14039、ISO4406、SAE4059cpc、SAE4059F、SAE749D、ГOCT17216、QC/T29104、JB/T9737、DLT432、HH005-2018 Waiting for more than ten commonly used standards

Support custom standard testing, naming and grading custom standards

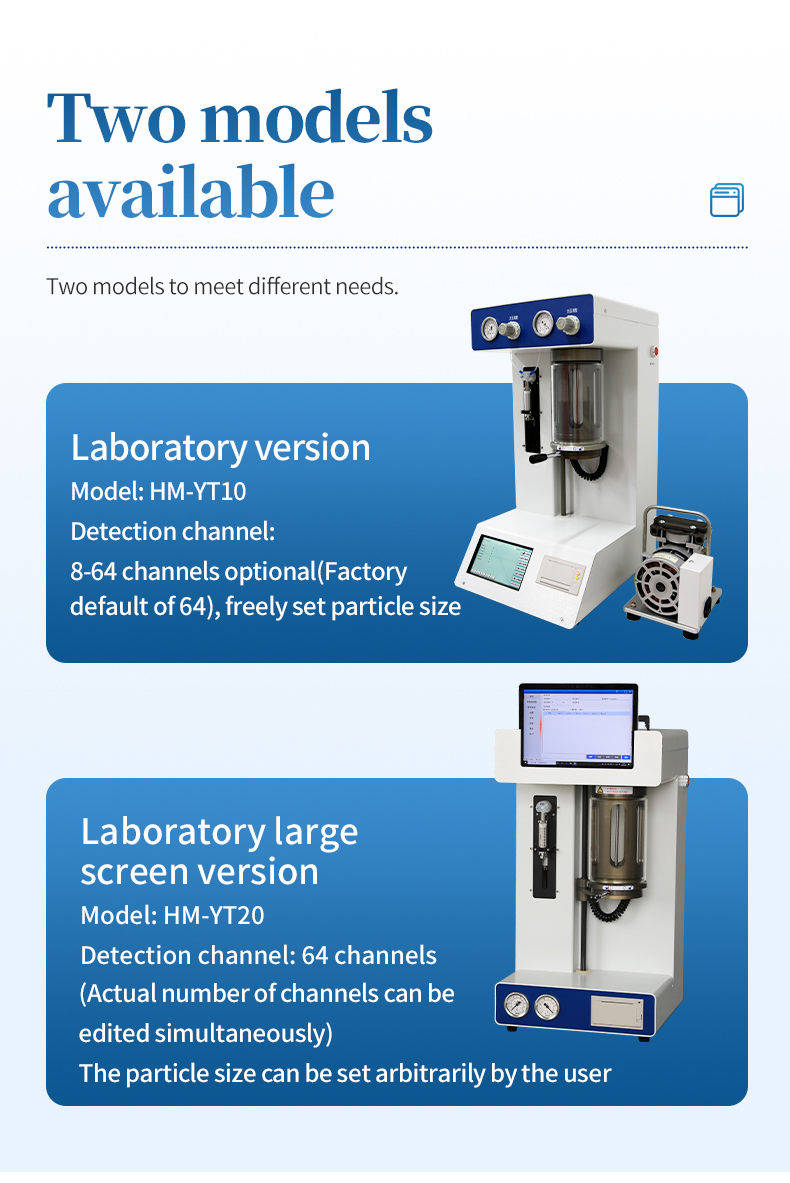

According to customer requirements, up to 64 detection channels can be set up simultaneously

Built in data analysis system, one test can provide all standard test data and pollution levels

Can perform cleaning detection, pre-set target cleaning requirements particle concentration, display cleaning status in real-time during the cleaning process, and automatically stop when the requirements are met

Built in viscosity, moisture, and temperature sensor modules provide viscosity, moisture saturation, ppm values, and temperature reference values (optional) while accurately testing particle distribution

The particle size can be set arbitrarily, with nearly 10000 built-in particle sizes for easy particle size analysis

Multiple sampling containers such as standard sampling bottles or cups can be used to meet the testing requirements of different industries

Fully functional 7-inch color touch screen operation, foldable button design, supports both Chinese and English interfaces, easy and convenient operation

Can perform manual, automatic, and semi counting calibration

Equipped with RS232 interface and supporting 485 communication, it can be connected to a computer or laboratory platform for data processing

It has massive data storage and printing functions, and supports USB storage. The data already stored on the machine can be exported to a USB drive

Having 5 or more account settings and separately setting operator permissions

Technical indicators

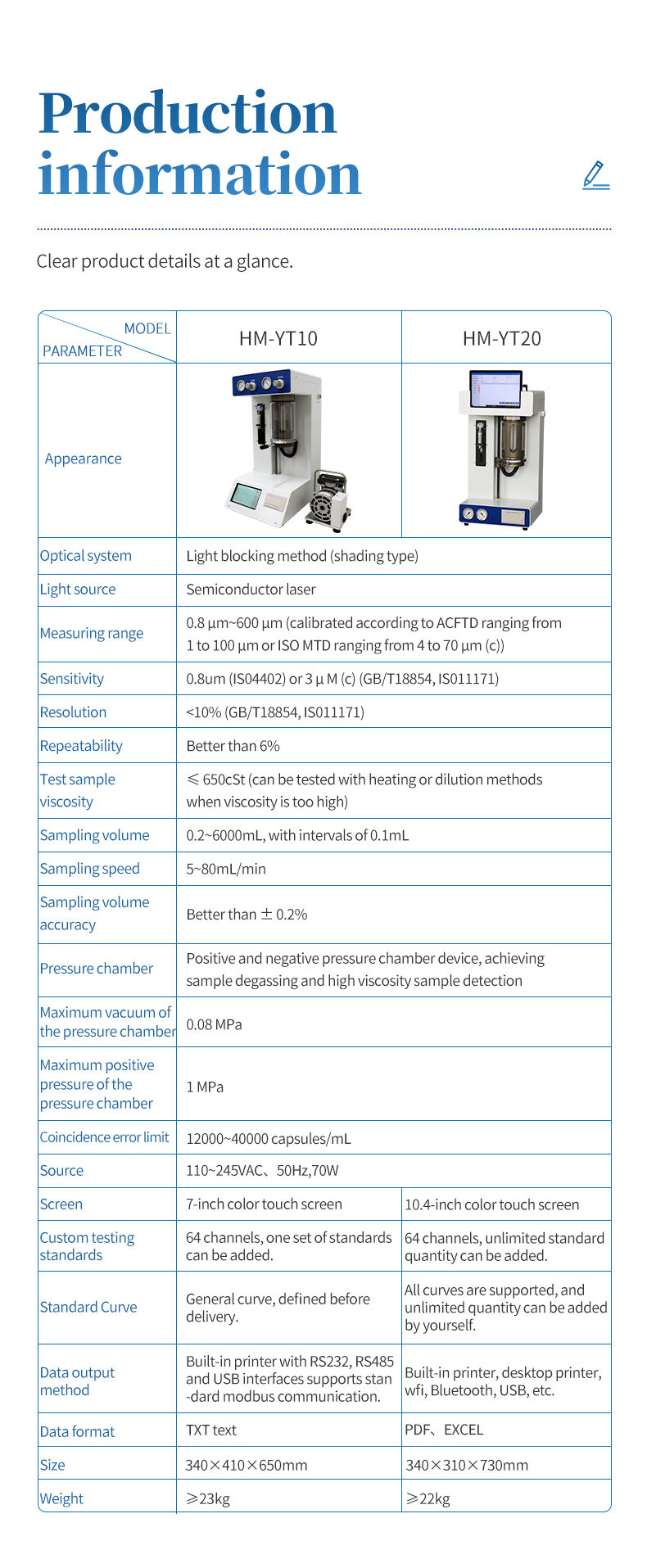

Light source: semiconductor laser

Particle size range: 0.8 μ m~600 μ m (calibrated according to ACFTD ranging from 1 to 100 μ m or ISO MTD ranging from 4 to 70 μ m (c))

Detection channels: 8-64 channels are optional (default 64 at the factory), and the particle size can be set arbitrarily

Sensitivity: 0.8 μ m (ISO4402) or 3 μ m (c) (GB/T18854, ISO11171)

Resolution: better than 6%

Repeatability: RSD<2%

Sample detection viscosity: ≤ 650cSt (excessive viscosity can be detected by heating or dilution methods)

Sampling volume: 0.2~6000mL, with an interval of 0.1mL

Sampling accuracy: better than ± 0.2%

Sampling speed: 5~80mL/min

Pressure chamber: positive and negative pressure chamber device, realizing sample degassing and high viscosity sample detection

Maximum vacuum in the pressure chamber: 0.08Mpa

Maximum positive pressure in the pressure chamber: 1 Mpa

Maximum particle concentration: 12000~40000 particles/mL

Temperature (paid optional): Collection range: 1-100 ℃; Collection accuracy: 1 ℃

Water activity (paid optional): Collection range: 1-100% RH; Collection accuracy: 1% RH

Moisture content (paid optional): Collection range: 1~360ppm; Collection accuracy: 1ppm

Test sample temperature: 0 ℃~80 ℃

Working temperature: -20 ℃~60 ℃

Storage temperature: -30 ℃~80 ℃

Power supply: 110~245V AC, 50/60Hz, 70W

Host size: 340mm × 410mm × 650mm

Air pump size: 180mm × 160mm × 220mm

Net weight of host: ≯ 23kg Net weight of air pump: ≯ 5.5kg

Article address:https://www.petrocheminstrum.com/pro1/61.html

- Previous: Hydraulic Oil Particle Counter

- Next: Oil Particle Size Analyzer