Product Center

Product details

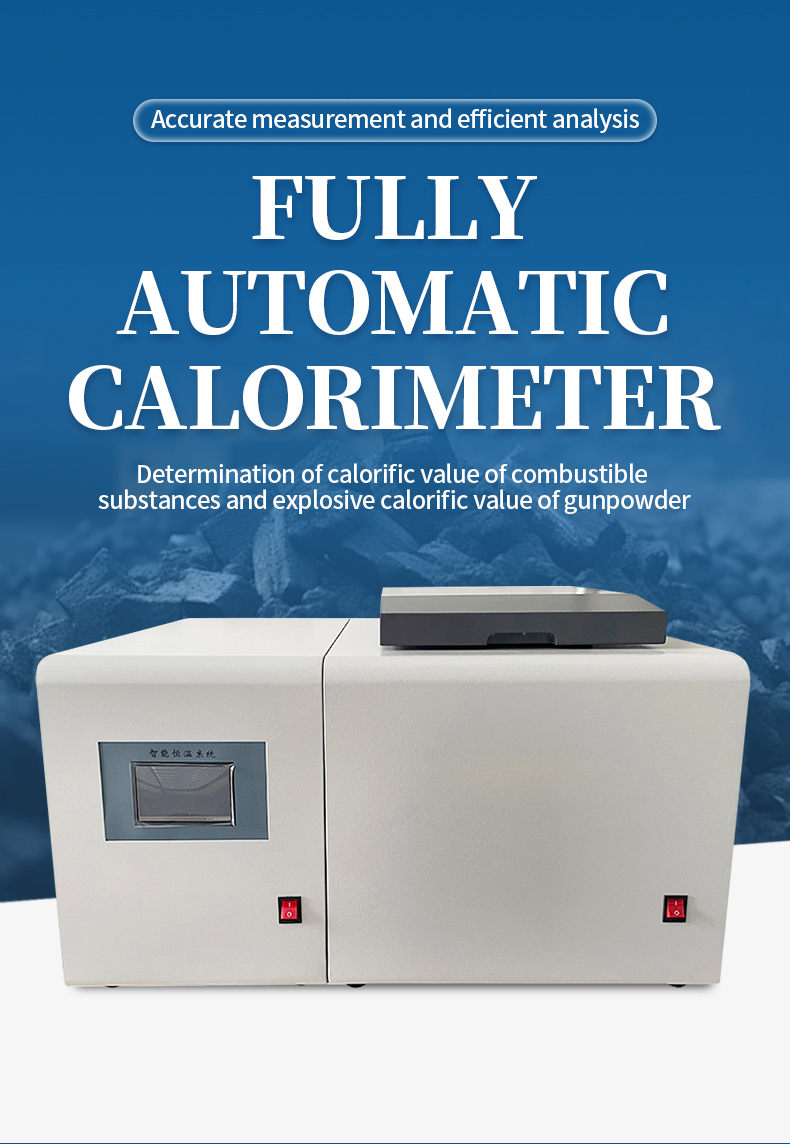

Product Introduction

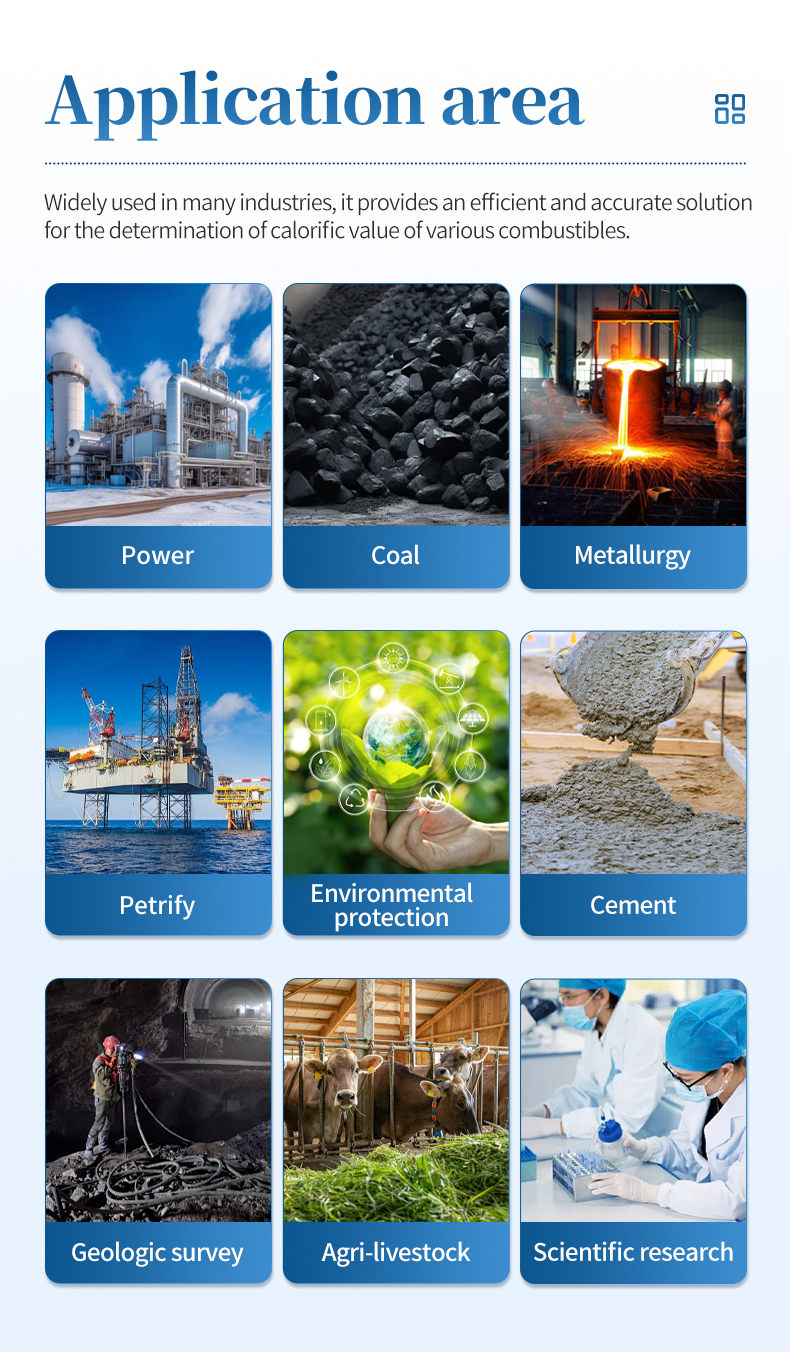

This instrument is suitable for measuring the calorific value of solid or liquid combustibles such as coal, petroleum, cement raw materials, grains, feed, etc. in industries or departments such as electricity, coal, metallurgy, petrochemicals, coalification, environmental protection, cement, papermaking, geological exploration, agriculture and animal husbandry, pharmaceutical research, and teaching.

Compliant with standards:

GB/T213-2008 "Method for determination of calorific value of coal"

GB/T384-1981 "Method for determination of calorific value of petroleum products"

JC/T1005-2006 "Method for determination of calorific value of cement black raw materials"

ASTM-D5865-2010 "Test Method for Total Calorific Value of Coal and Coking Coal"

GB/T30727-2014 "Method for determination of calorific value of solid biomass fuels"

The requirements of ISO 1928-2009 "Solid mineral fuels - Determination of total value and calculation of net calorific value using a bomb calorimeter".

Features:

It mainly consists of a constant temperature calorimeter system and a single-chip microcomputer control system, and is a highly automated heat measurement instrument that is automatically controlled by a single-chip microcomputer system and capable of data processing;

This instrument is mainly used for measuring the heat generation of combustible substances such as coal, petroleum, chemical, food, wood, explosives, etc. At the same time as measuring the heat generation of the cartridge, it converts the corresponding high and low heat generation.

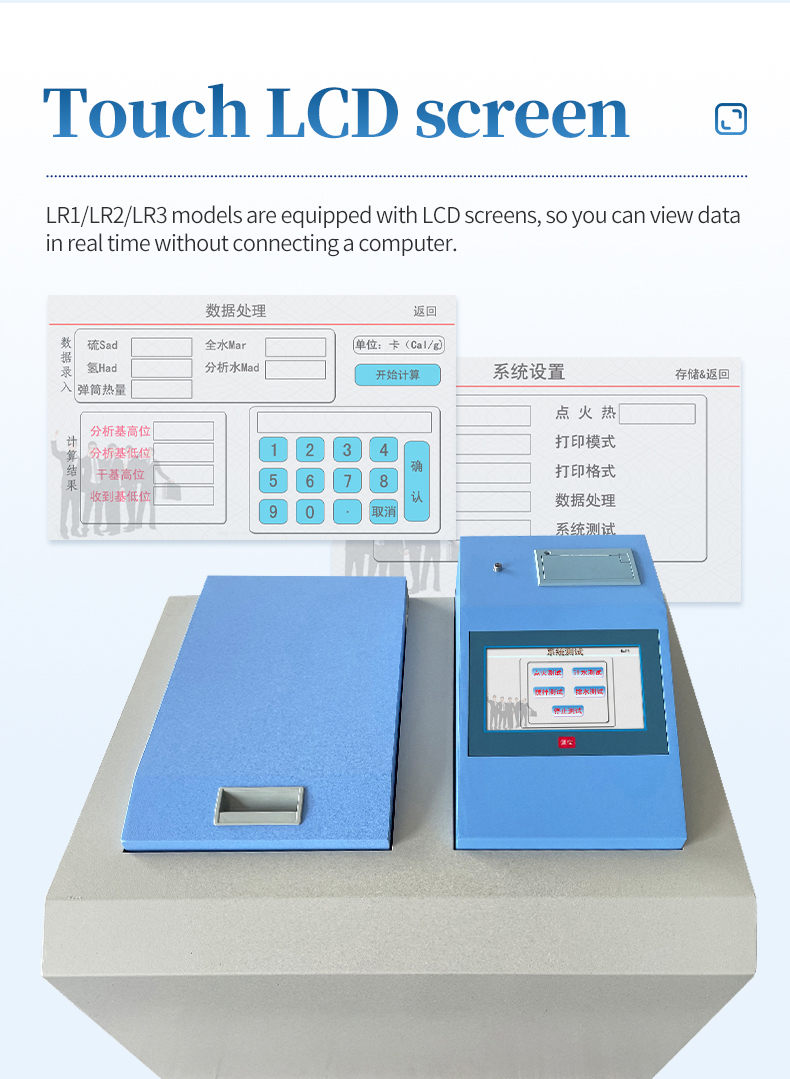

Adopting advanced technology from the United States for touch sensitive LCD screens, the integrated installation method ensures the firmness of the touch screen.

Infrared technology, using CRT display materials to make the touch screen more durable. Multi layer composite film coverage ensures optimal color distortion, reflectivity, and clarity, with sensitive sensing and high positioning accuracy. The effective coverage area is up to 90% wear-resistant, and the lifespan can reach up to 10 years.

Chinese characters are displayed and can be operated directly without the need for an external computer. Can store over 1000 data points and display temperature rise curves.

Adopting an advanced microcontroller system, the operation is fully automated. All that is required manually is weighing, loading ammunition, and oxygenation. The instrument automatically completes tasks such as quantitative water injection, automatic mixing, ignition, output printing results, and drainage.

Reasonable structure, excellent production, reliable performance, and low failure rate. The results are accurate, and a unique cooling calibration system is adopted to ensure the long-term stability of the instrument performance.

Controlled by a microcomputer, it can provide coal quality reports, with human-machine interaction, and can be learned immediately. Automatic water injection and drainage, no need to adjust the water temperature, just install an oxygen bomb into the cylinder, and the instrument will automatically complete all the measurement and testing work.

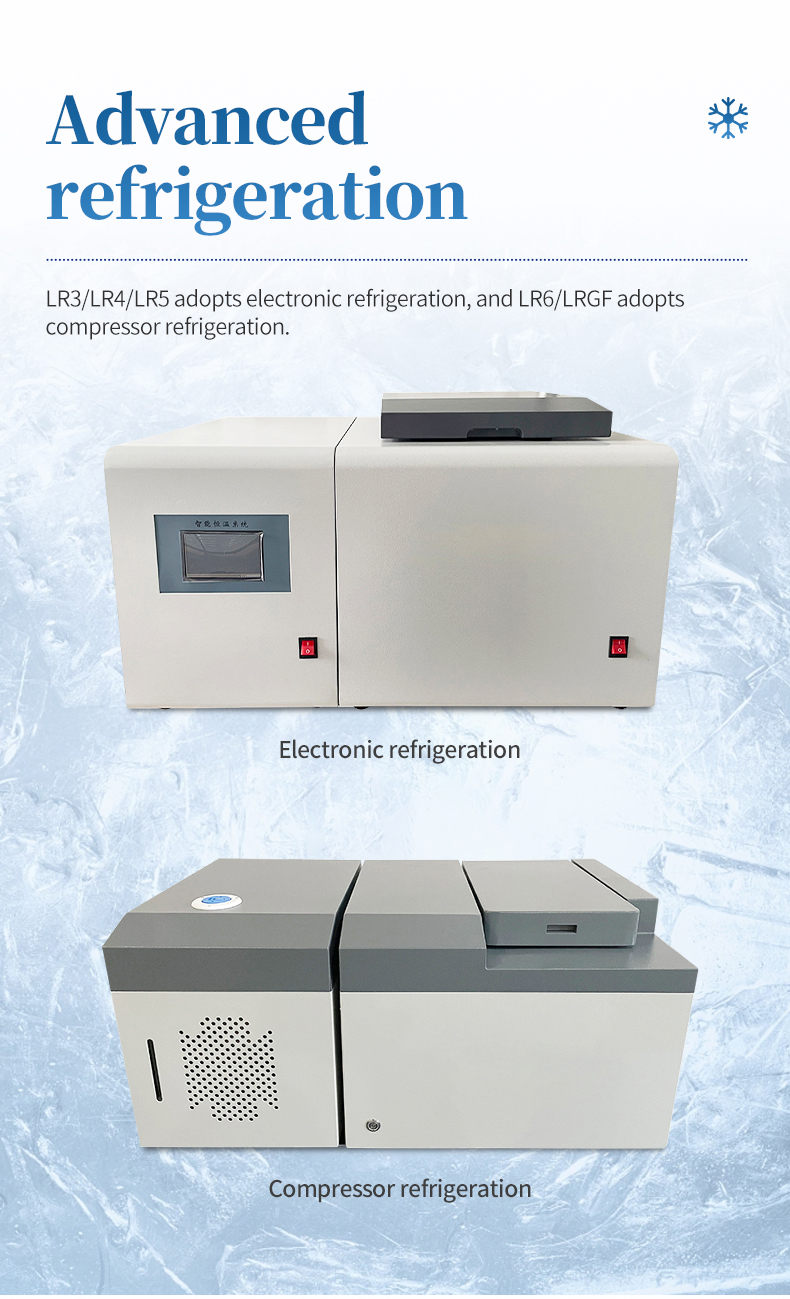

The structure is accurate, and a unique cooling calibration system is adopted to ensure the long-term stability of the instrument performance. Advanced electronic refrigeration technology, completely unaffected by environmental temperature changes, ensures that the temperature difference between the inner and outer cylinders of the instrument meets national standards. Can work continuously for a long time.

Stainless steel vacuum inner cylinder. The mixing system adopts German imported motors.

The testing speed is fast, with a testing cycle of ≤ 8min (rapid method) ≤ 15min. The repeatability and reproducibility of the calorific value test are better than the requirements of the national standards GB/T384 "Determination of Calorific Value of Petroleum Products", GB/T213-2008 "Requirements for Determination of Calorific Value of Coal", ISO1716 "Reaction to Fire Test for Building Products - Determination of Combustion Calorific Value", and GB/T 14402-2007 "Determination of Combustion Performance and Combustion Calorific Value of Building Materials and Products".

This product has excellent performance and reliability even when operating in harsh environments.

High degree of automation, automatic utilization of the water volume in the built-in fixed container, automatic control of the temperature difference between the inner and outer buckets of the instrument, and automatic completion of the entire experimental process.

The data processing function is rich, and users can easily query historical experimental data, current day data, parallel sample data, etc.

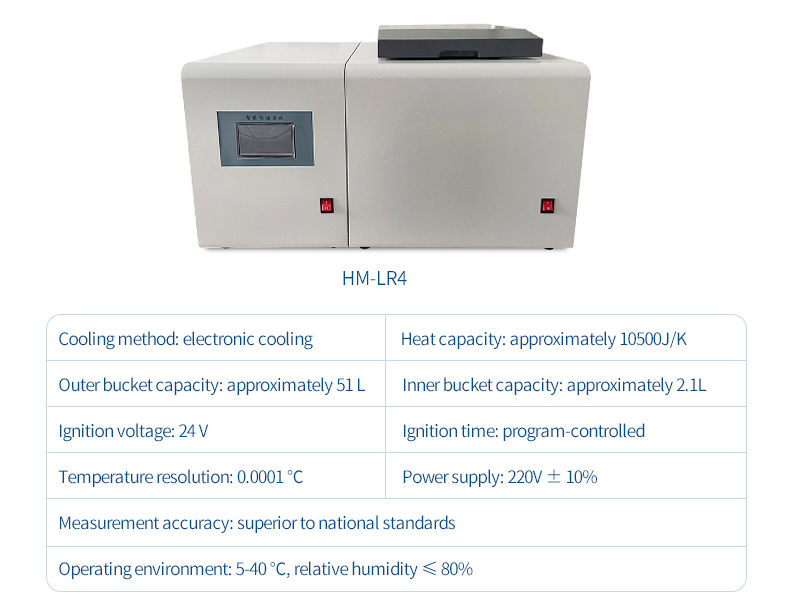

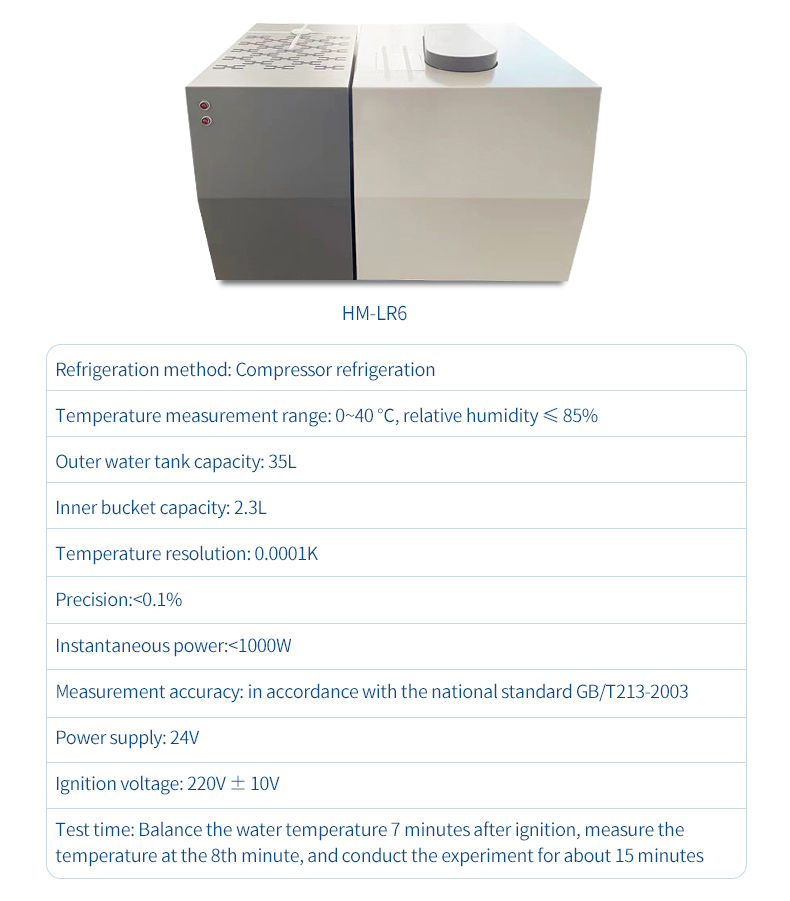

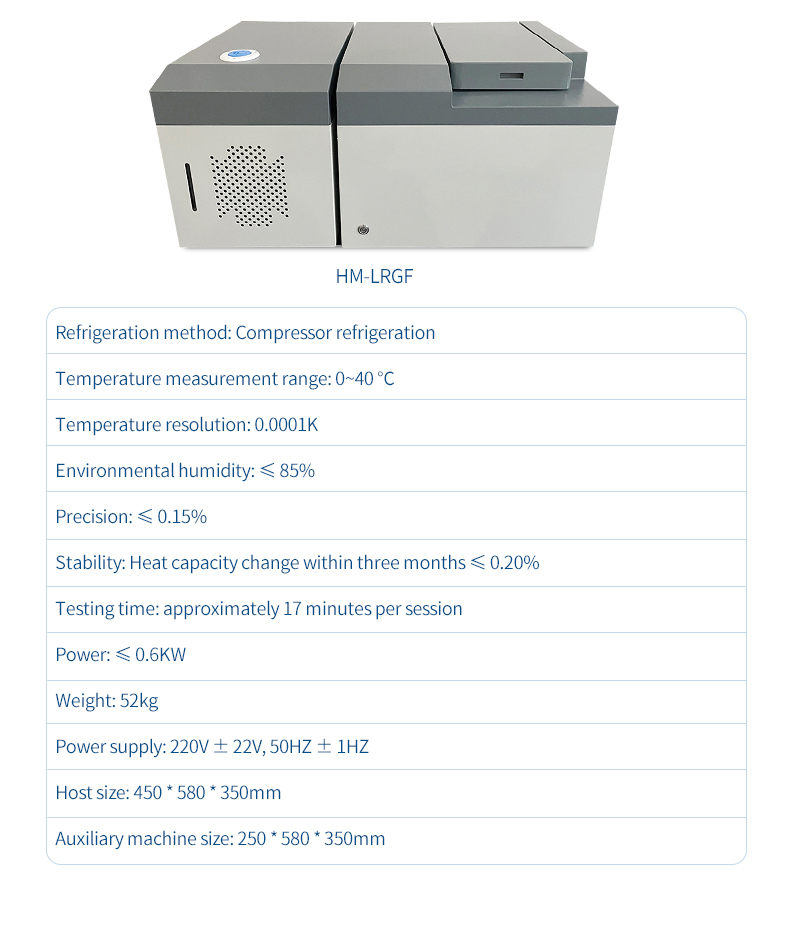

Technical Specifications:

Heat capacity: approximately 10500 J/K Oxygen bomb capacity: 300ml

Oxygenation pressure: 2.8~3.2 MPa Pressure resistance: Water pressure 20MPa

Weight: 25 Kg Dimensions: ф 86.2 × 181 mm

Temperature range: 0~40 ℃ Response time:<4 seconds

Resolution: 0.0001 ℃ Linearity:<0.08% within every 5 ℃ temperature rise range

Humidity: ≤ 80% Temperature measurement error: Temperature rise range accuracy of ± 0.003 ℃ every 5 ℃

Supply voltage: AC220V ± 10% Power: 30W

Ignition time: 5 seconds

Article address:https://www.petrocheminstrum.com/pro10/50.html

- Previous: Oxygen Bomb Calorimeter

- Next: Fully Automatic Calorimeter