Product Center

Solidification Point Pour Point Tester HM-NQ

Product details

Product Introduction:

The fully automatic pour point analyzer is mainly used for measuring the pour point value of petroleum products. It is a pour point/pour point measurement equipment that integrates automation, intelligence, and high precision. Through innovative temperature control technology and automatic air pressure detection system, the pour point and pour point of liquid samples can be quickly and accurately determined.

Detection principle:

Using the automatic pressure method, preheat the sample (45 ℃ or expected value+9 ℃) and then cool it down according to the specified cooling rate. The sample temperature starts from the expected value+15 ℃ and undergoes automatic pressure testing every 1 ℃. The experimental results are completely consistent with the tilt method described in GB/T 510, ISO3016, and ASTM D97.

Execution standards:

ASTM D6749;

SN/T 3017。

Advantages and Characteristics:

1. ★ Convenient sealing design: Adopting elbow clamp compression sealing, simple operation and reliable sealing, automatic detection of air leakage and alarm.

2. ★ Fully automatic testing process: No need for pre pumping, intelligent control of the air pump for cyclic operation, protecting internal components.

3. ★ Semiconductor refrigeration technology: intelligent protection of refrigeration chips, real-time monitoring of water cooling temperature, automatic shutdown alarm for abnormal situations.

4. Accurate standard sample testing: Strictly comply with the ± 6 ℃ detection range, and both -16.5 ℃ and -50 ℃ samples are verified to be reliable.

5. ★ Standard compliant cooling: segmented temperature control (-3~4 ℃/min and -0.8~1.1 ℃/min).

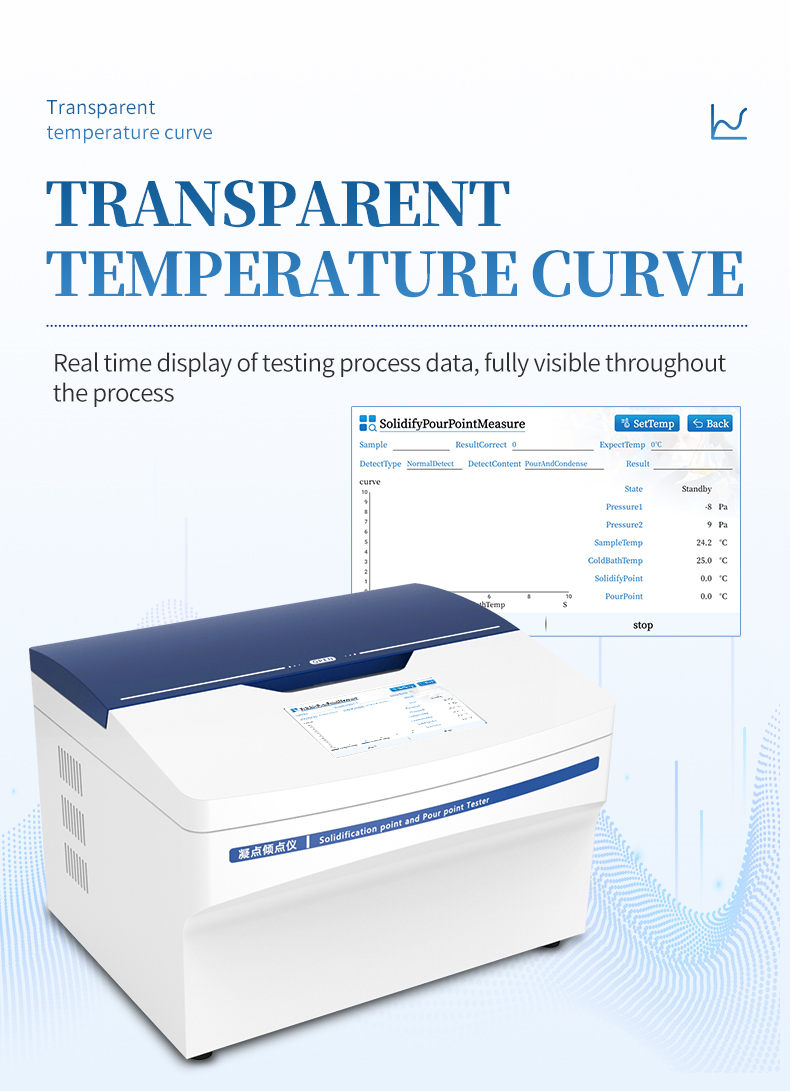

6. ★ Transparent temperature curve: Real time display of test process data, visible to customers throughout the entire process.

Technical parameters:

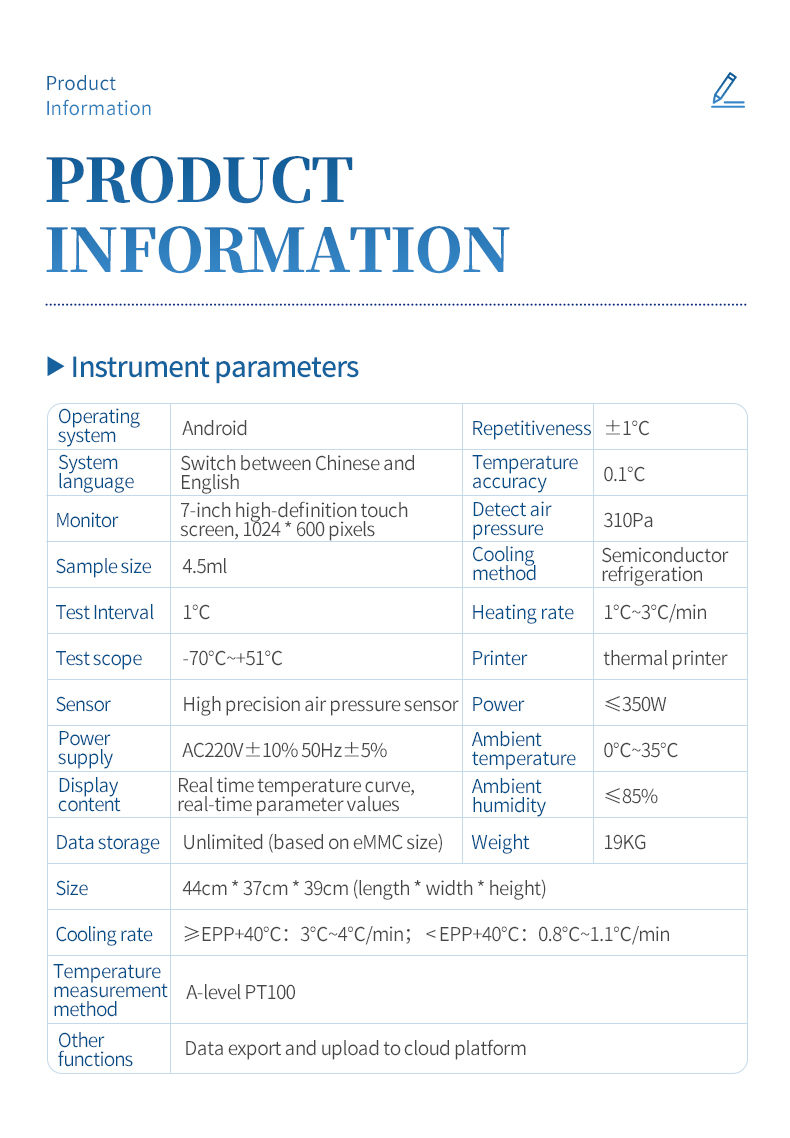

Operating System: Android

System language: Switch between Chinese and English

Display: 7-inch high-definition touch screen, 1024 * 600 pixels

Sample size: 4.5ml

Test interval: 1 ℃

Test range: -70 ℃~+51 ℃

Repeatability: ± 1 ℃

Temperature measurement method: Class A PT100

Temperature accuracy: 0.1 ℃

Detecting air pressure: 310Pa

Sensor: High precision air pressure sensor

Cooling method: semiconductor cooling

Heating rate: 1 ℃~3 ℃/min

Cooling rate: ≥ EPP+40 ℃: 3 ℃~4 ℃/min; < EPP+40℃:0.8℃~1.1℃/min

Display content: Real time temperature curve, real-time parameter values

Data storage: unlimited (based on eMMC size)

Other functions: data export, data upload to cloud platform

Printer: Thermal printer

Power supply: AC220V ± 10% 50Hz ± 5%

Power: ≤ 350W

Environmental temperature: 0 ℃~35 ℃

Environmental humidity: ≤ 85%

Size: 44cm * 37cm * 39cm (length * width * height)

Weight: 19KG

Article address:https://www.petrocheminstrum.com/pro4/31.html

- Previous: no more

- Next: no more