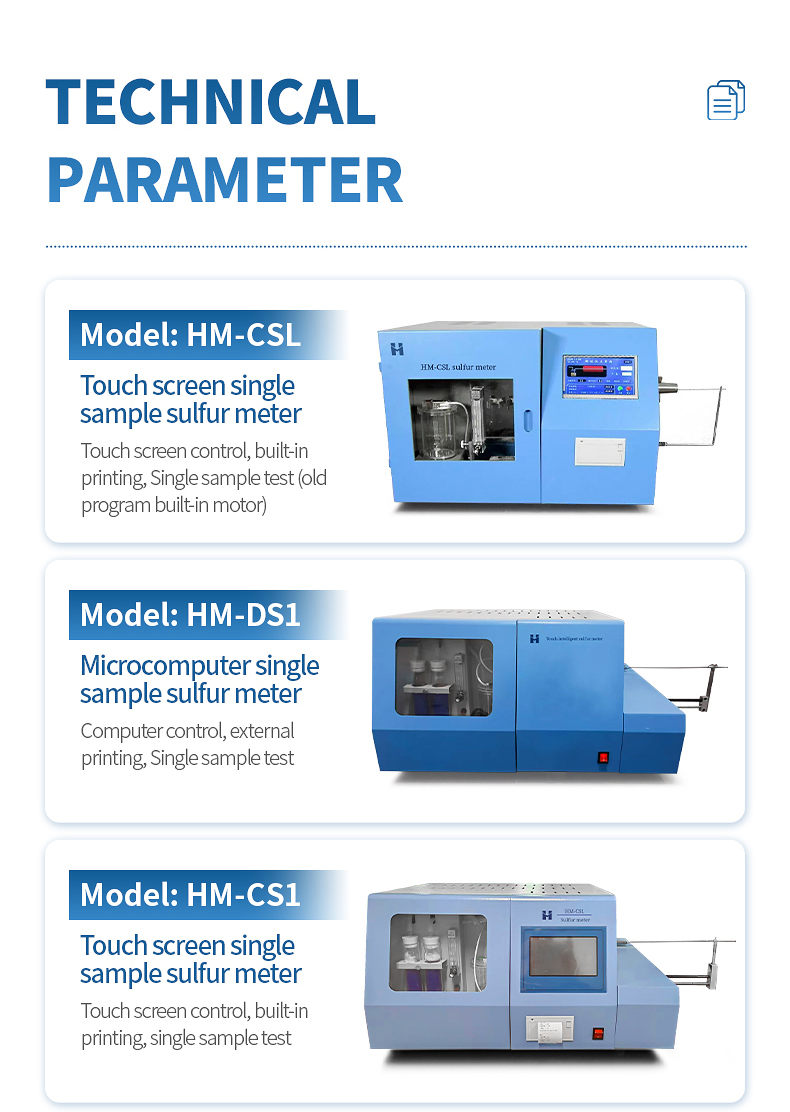

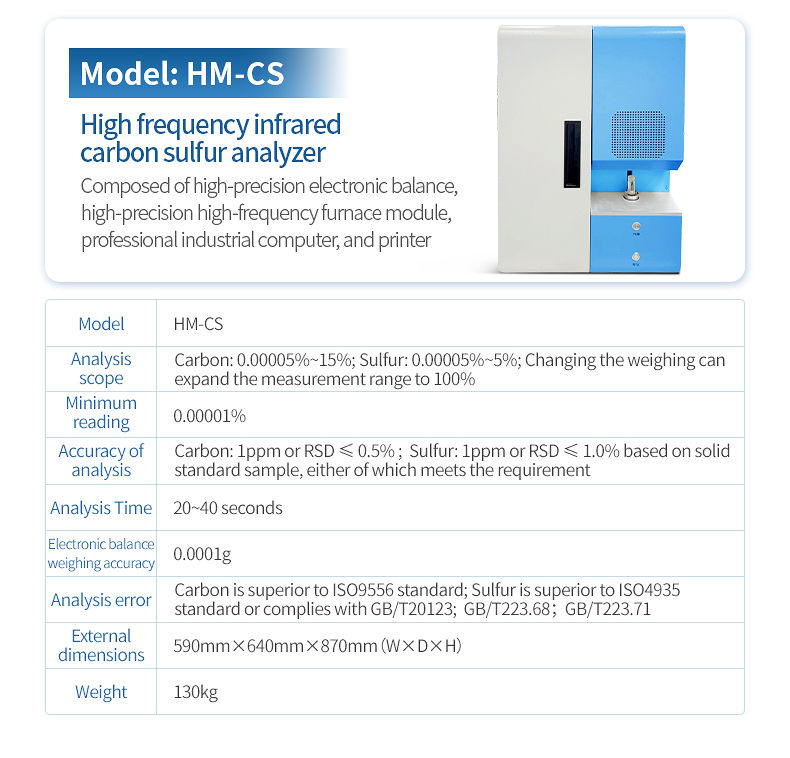

Product Center

Microcomputer Single Sample Sulfur Analyzer HM-DS1

Product details

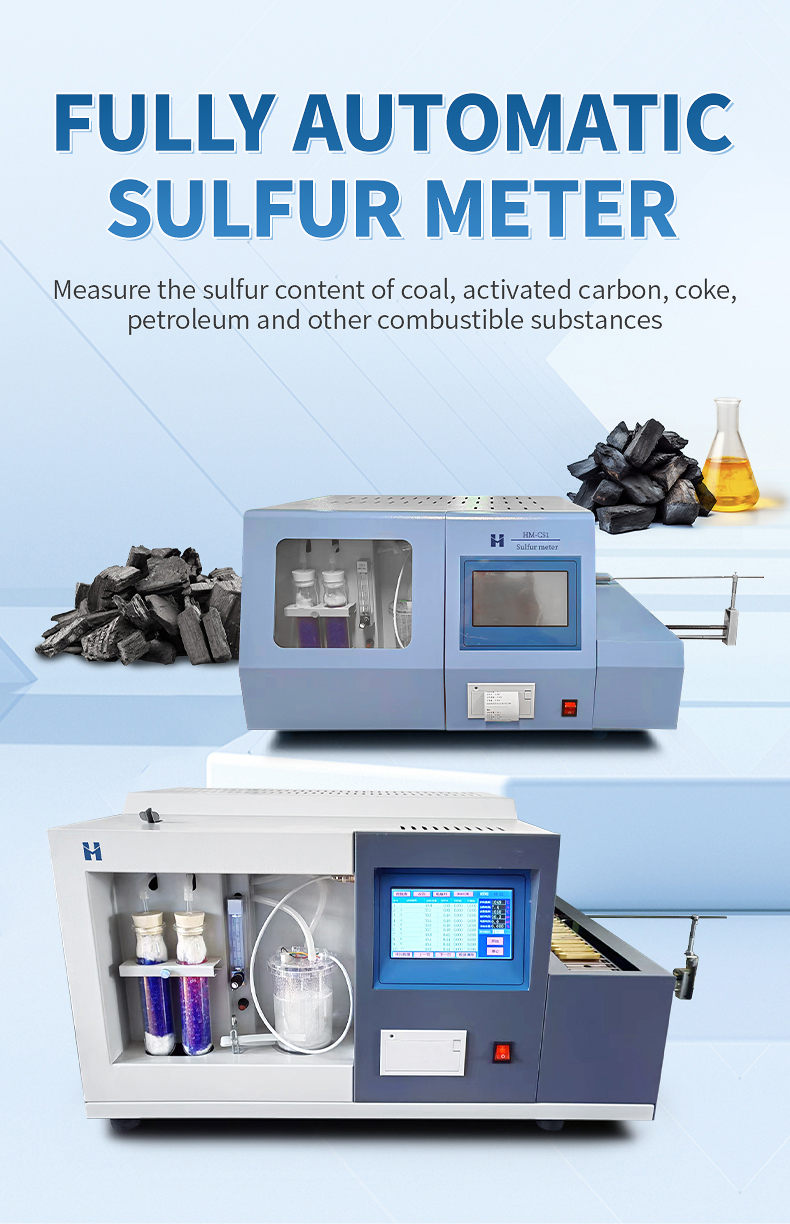

The microcomputer single sample sulfur analyzer is used to determine the total sulfur content in coal, activated carbon, steel, petroleum, biomass, and various minerals. It is a commonly used instrument in laboratories of coal, power, chemical, building materials, metallurgy, geological exploration, and other departments. Meets the requirements of GB/214-2007 "Method for determination of total sulfur in coal".

Overview of System Functions

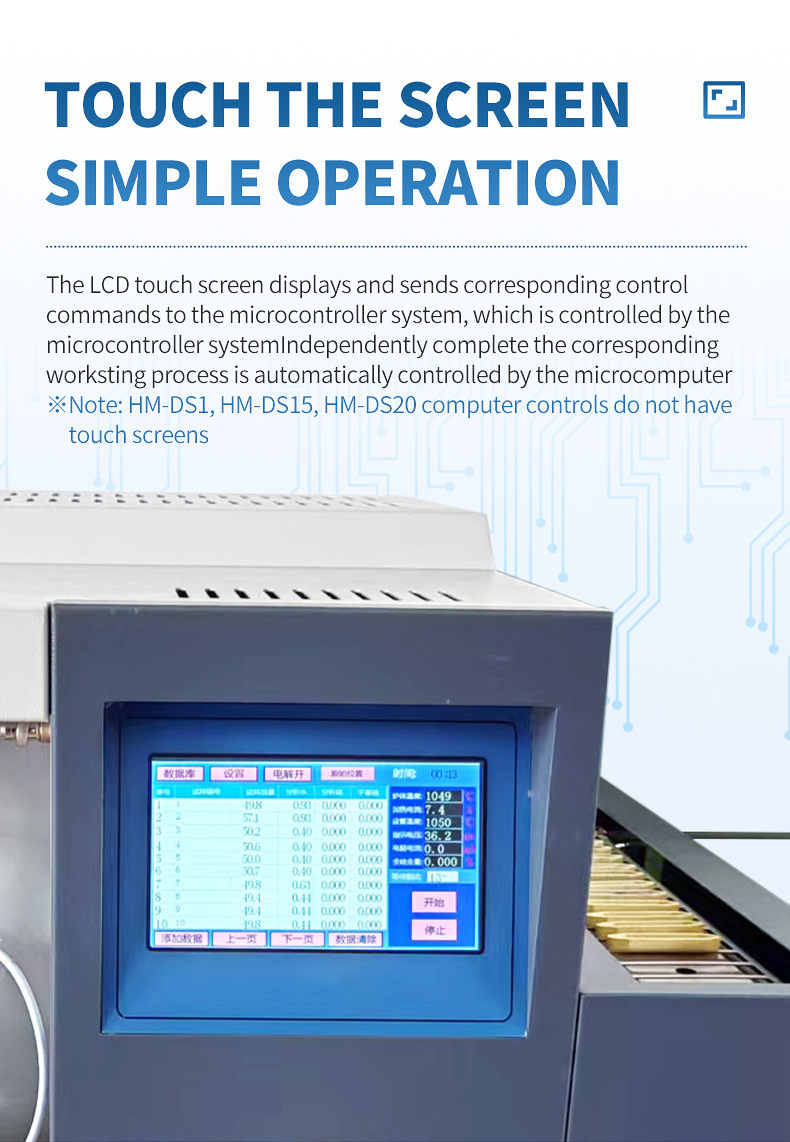

1. The entire testing process is automatically completed by computer control.

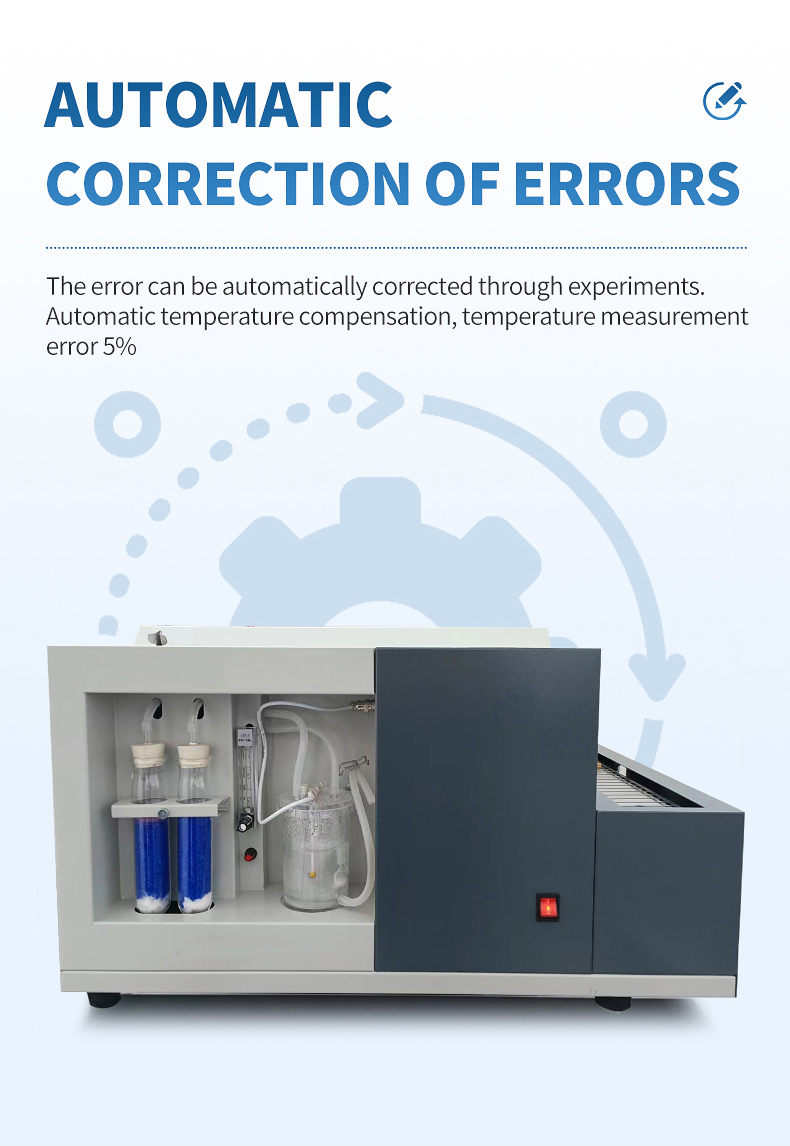

2. Errors can be automatically corrected through experiments.

3. The test results are permanently saved and can be viewed and printed.

4. Automatic temperature compensation, with a temperature measurement error of 5%.

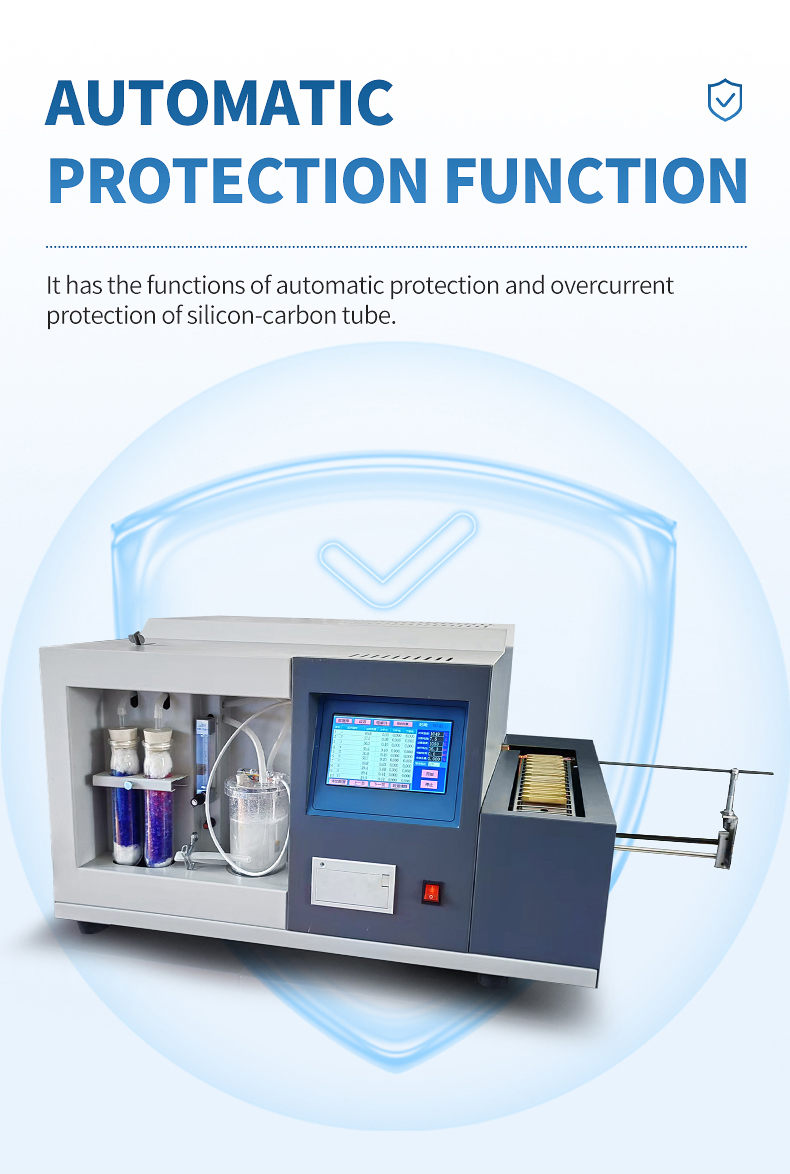

5. It has functions such as automatic startup protection and overcurrent protection for silicon carbon tubes.

6. This system places the high-temperature furnace, magnetic stirrer, air purification device, electrolytic cell, automatic sample delivery mechanism, and microcontroller control circuit in the same chassis, making the entire system beautiful, small in size, easy to place and connect, and simple to operate and maintain.

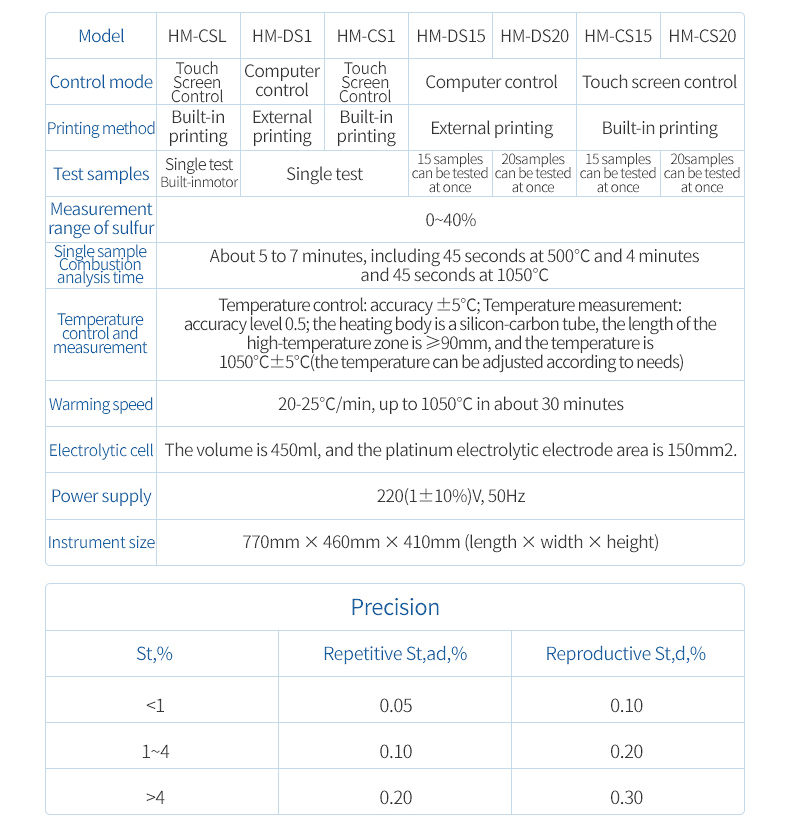

Main technical indicators

1. The measurement range of sulfur is 0-40%

2. Single sample combustion analysis time: about 5-7 minutes, including 45 seconds at 500 ℃ and 4 minutes and 45 seconds at 1050 ℃.

3. Temperature control: accuracy ± 5 ℃. Temperature measurement: accuracy level 0.5; The heating element is a silicon carbon tube, with a high temperature zone length of ≥ 90 millimeters and a temperature of 1050 ℃± 5 ℃ (temperature can be adjusted as needed)

4. Density: As specified in the table below:

St,% | Repetitive St, ad,% | Reproducible St, d,% |

<1 | 0.05 | 0.10 |

1—4 | 0.10 | 0.20 |

>4 | 0.20 | 0.30 |

5. Heating rate: 20-25 ℃/min, can reach 1050 ℃ in about 30 minutes.

6. Electrolytic cell: with a volume of 450 milliliters and a platinum electrolysis electrode area of 150mm2.

7. Power supply: 220 (1 ± 10%) V, 50Hz,

8. Power: ≤ 3KW.

9. Instrument dimensions (mm) length x width x height (770 x 460 x 410)

Article address:https://www.petrocheminstrum.com/pro9/36.html